Every industrial, commercial, or specialized piping project comes with unique challenges—non-standard pipe diameters, harsh environmental conditions, or strict aesthetic and regulatory demands. Off-the-shelf clamps often fall short, forcing compromises that risk leaks, reduced durability, or non-compliance. Our customizable clamp solutions eliminate these trade-offs, offering tailored sizes, finishes, and configurations to align perfectly with your specific piping needs. This article explores how our bespoke approach ensures optimal performance, reliability, and efficiency for your unique applications.

Size Customization: Beyond Standard Dimensions

One of the most common pain points with standard clamps is mismatched sizing, which can lead to insecure fits, pipe damage, or system failures. We specialize in creating clamps across a wide range of custom sizes, from micro-clamps for small-diameter medical or electronics piping to extra-large heavy-duty clamps for industrial infrastructure projects.

Our size customization process starts with a detailed consultation to understand your pipe’s outer diameter (OD), wall thickness, and fitting specifications. Using precision engineering tools and advanced manufacturing techniques, we produce clamps with exact adjustment ranges—ensuring a snug, non-damaging fit that maintains leak-tight performance even under pressure or vibration. Whether you need a clamp for a 5mm laboratory tube or a 500mm industrial pipe, we can tailor the band width, diameter range, and hardware to match your exact requirements.

Finish Customization: Durability & Compliance for Any Environment

The right surface finish is critical for clamp longevity, corrosion resistance, and compliance with industry standards. We offer a comprehensive range of custom finishes to suit diverse environments, from corrosive marine settings to hygiene-critical food processing facilities:

-

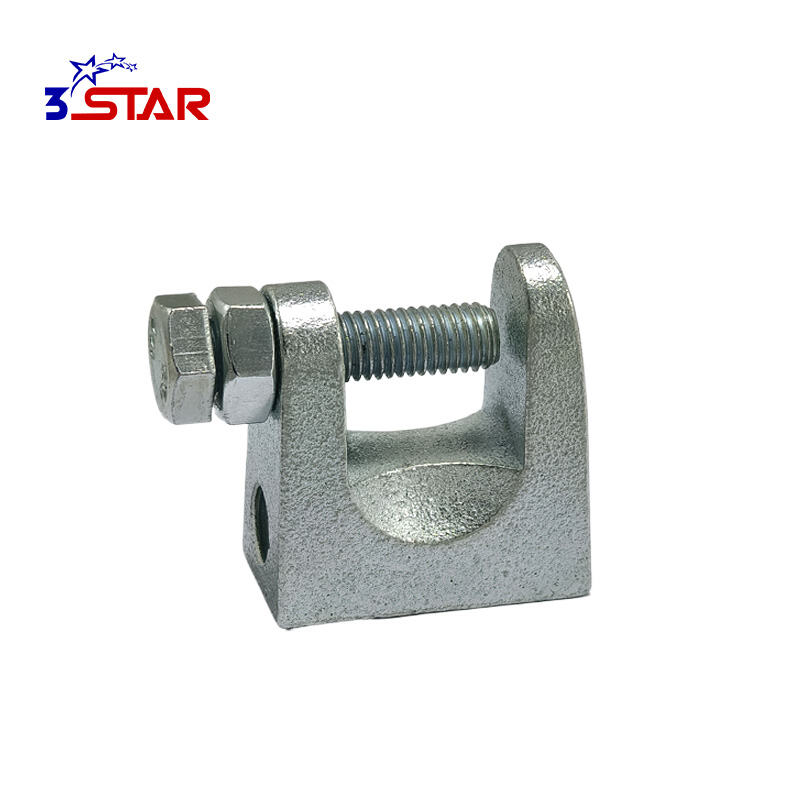

Corrosion-Resistant Finishes: For outdoor, coastal, or chemical-exposed applications, we provide zinc plating, hot-dip galvanizing, or passivation treatments—ideal for carbon steel or stainless steel clamps. These finishes create a protective barrier against rust, salt, and chemical degradation.

-

Hygienic Finishes: For food, beverage, and pharmaceutical projects, we offer electropolishing or mirror polishing for stainless steel clamps. These smooth, crevice-free finishes prevent bacterial growth and meet FDA, 3-A, and other sanitary standards.

-

Aesthetic & Specialty Finishes: For architectural or visible piping systems, we provide powder coating in custom colors to match your brand or design scheme. We also offer anti-static or high-temperature finishes for specialized industrial applications.

Tailored to Diverse Industry Applications

Our customizable clamps are engineered to meet the unique demands of various sectors. For example, in renewable energy projects, we create large-diameter, corrosion-resistant clamps to secure piping in solar thermal or wind power plants. In automotive manufacturing, we produce custom-sized T-bolt clamps for high-pressure turbo systems. For agricultural irrigation, we tailor plastic or stainless steel clamps to fit irregular hose sizes and withstand harsh field conditions.

We also accommodate specialized requirements, such as flame-retardant materials for oil and gas applications or non-conductive finishes for electrical piping systems. Our team works closely with you to identify potential challenges and design a clamp solution that addresses your project’s specific needs.

Streamlined Customization Process: From Consultation to Delivery

We understand that time is critical for your projects, so we’ve streamlined our customization process to ensure quick turnaround without compromising quality:

-

Consultation: Share your project specifications, including pipe dimensions, environment, and performance requirements with our team.

-

Design & Prototyping: Our engineers create a custom clamp design and, if needed, produce a prototype for your approval.

-

Manufacturing: We use advanced production techniques to manufacture the custom clamps, adhering to strict quality control standards.

-

Delivery: We ship the finished clamps with detailed documentation, ensuring compliance with your project’s requirements.

Off-the-shelf clamps force you to adapt your project to standard solutions—but with our customizable clamp options, your piping system gets a solution built specifically for it. By tailoring sizes, finishes, and configurations, we ensure your clamps deliver optimal performance, durability, and compliance, reducing maintenance costs and minimizing downtime. Contact our team today to discuss your unique piping requirements and discover how our custom clamp solutions can elevate your project.

Hot News

Hot News