The main function of heavy duty clamp is to ensure the perfect combination of pipeline and hose, and to ensure the safety and sealing of the conveying medium. The heavy duty is named because of its strong fastening force.It is cost-effective, strong fastening force and easy to operate. Which type can be called heavy duty clamp?

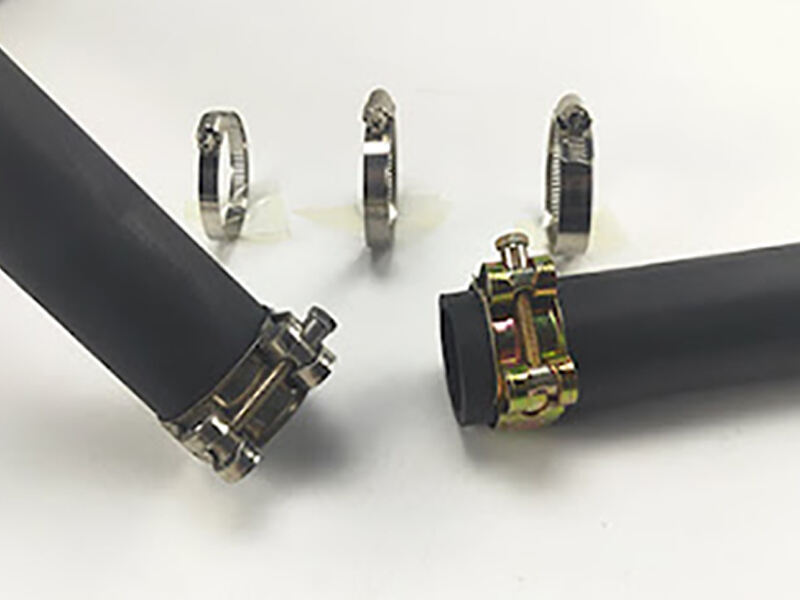

There are roughly several types of heavy duty clamp: European clamps, T-type clamps, and Tiger spiral clamp. These types have strong fastening force due to material selection and design.

Heavy duty clamps are generally made of stainless steel and carbon steel galvanized materials.

Different materials have different application ranges.For carbon steel galvanized material is generally in dry environment. Stainless steel material is mostly used in humid environment.

The quality of heavy duty clamp mainly depends on the width and thickness of the steel belt. The second is the strength of the screws and nuts. The third is the degree of standardization of the model.

In order to ensure the service life of clamp, it is recommended to strictly follow the regulations during use.

Hot News

Hot News2026-01-30

2026-01-16

2026-01-09

2025-12-31

2025-12-24

2025-12-22