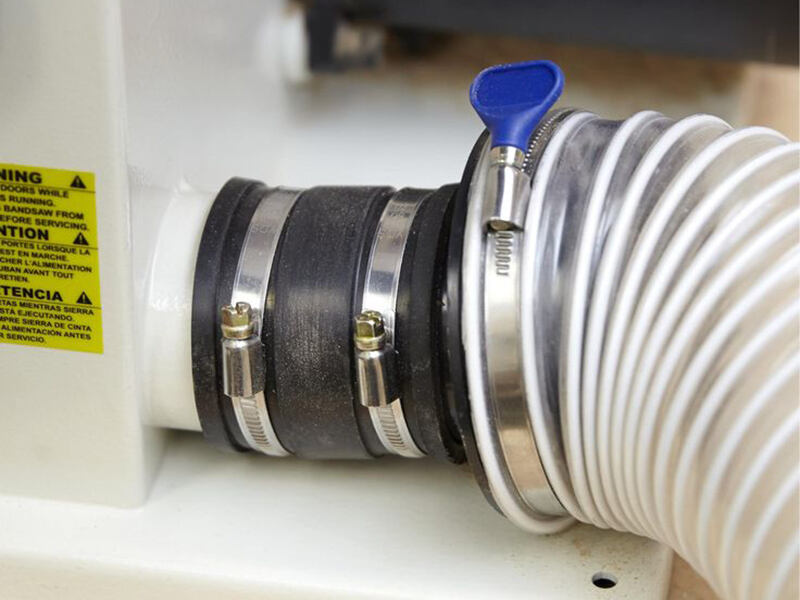

Hose clamps are parts that tightly connect the hoses of mechanical equipment. They are tightened by screws and nuts, and the tightening range of the steel belt is reduced to play a tightening role. The names are different in each country and region. The application range of each hose clamp is also different.

European hose clamps are used for thick-walled hoses.

British hose clamps (11.7mm) are professional fire hose tightening.

Tiger spiral clamps are mainly used for hoses that require strong tightening force.

American worm drive hose clamps are widely used. There are three types of worm gear clamps: The main difference between American hose clamps is the width of the steel belt. The distinction between semi-steel and full-steel is distinguished by the clamp head. The steel belt is made of stainless steel. The semi-steel clamp head screw is made of iron nickel-plated material, which looks like stainless steel. As the name suggests, the material of the entire hose clamp is stainless steel. The steel belt adopts the hollow process, and the screws and steel belt are perfectly combined.

The width of the German type hose clamp steel belt (9mm) is similar to that of the American type, and is mainly used for fastening the connection of automobile pipelines. The material is divided into semi-steel and full steel. The difference from the American hose clamp is that the steel belt is not hollow, but stamped teeth, which are tightly combined with the screws.

Hot News

Hot News2026-01-30

2026-01-16

2026-01-09

2025-12-31

2025-12-24

2025-12-22